Electric tapping machines have become indispensable tools in various industries, providing unparalleled efficiency and precision in threading and tapping operations. These innovative machines, powered by electricity, revolutionise the way threads are cut into materials such as metal and plastic and enhance manufacturing processes.

Powering precision

According to Daisy Digest, electric tapping machines are designed with a primary objective: to create threads with accuracy and speed.

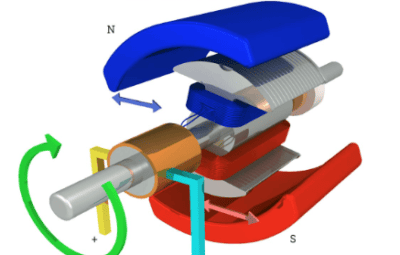

The first key element in the functionality of the electric tapping machine is the electric motor. This motor, typically powered by electricity, drives the entire tapping process. It provides the necessary torque and rotational power required to cut threads into the material. The electric motor ensures a consistent and controlled rotation, which is crucial in achieving precise threading.

Accompanying the electric motor is a gearbox that regulates the speed and torque, allowing for customisation based on the material being worked on and the desired thread specifications. This gearing mechanism plays a pivotal role in adapting the machine’s performance for different applications, making electric tapping machines versatile tools suitable for various industries.

Tapping into efficiency

The heart of electric tapping machines lies in the tapping head. This component houses the tap, which is the tool responsible for cutting threads into the material. The tapping head moves in a controlled vertical motion, guided by a spindle. The combination of the spindle and tapping head ensures the tap follows a precise path, resulting in accurately threaded holes.

Electric tapping machines often come equipped with features such as automatic reverse and depth control. These additions enhance the efficiency of the tapping process by reducing manual intervention and minimising errors. The automatic reverse feature allows the tap to retract once the desired depth is reached, while depth control ensures uniform threading across multiple workpieces.